The Art of the Embossing Process

By: phase1

The embossing process offers a satisfying detail that appeals to our sense of touch and adds visual depth. Neuromarketing tells us all about how powerful the sense of touch can be to purchasing decisions. It makes us feel more of a sense of ownership and connects to us on a deeper level.

Embossing printing uses an artistic approach to imprint images into a surface. It can be done in a variety of marketing efforts, including packaging. Embossing is a simple, affordable way to add a rich, haptic experience to an array of products. Keep reading to find out more about embossing art, including its benefits, applications and the embossing process.

What Is Embossing?

Embossing is the impression or relief of a design onto another surface. These surfaces can include paper, metal, cloth and more, while the art can be as simple as basic lettering or as complex as multi-level decorations and patterns.

Though we generally refer to the practice as embossing, there are actually two types — embossing and debossing. When a design presses below the surface of the paper, it is debossed. When it rises above the page, it is embossed. Both are done similarly.

In either case, there are two metal plates, called dies. One has the design engraved into it, and the other, a counter die, holds the inverse of the cutout. The plate and counter die sandwich the surface between them and apply pressure. The dies can include a variety of materials and complexities, with some designed for very short print runs and others designed for long-term use. Another feature specific to some metals is the ability to hand-tool the design.

Many embossing projects will also use foils or inks in conjunction with the raised image. These materials can add clarity to a design or make an image more eye-catching. Images, accents and texts all tend to look good with foils and inks.

Embossing is unique in that it is both aesthetic and functional. It is attractive, adding a dimensional finish to any design and making it pop. It can also be functional through its sensory involvement, bringing people into a haptic experience.

Accessibility also plays a role in embossing, as braille often makes use of the technique.

The Benefits of Embossing

From beautifully elegant bottles of finely aged wine to a collection of decadent chocolates, embossing offers more than just a pretty face to your product. It can influence a variety of aspects of your marketing, including your brand’s image, the interaction a customer has with the product and the options you have for production.

1. Branding

Many brands benefit from the feel of an embossed design. They evoke a feeling of luxury, of high-end merchandise, which brings added value to premium products like liquor, hotels and fine dining. Very simple embossings can go a long way in adding a touch of class. If you sell a product as an experience, embossing can be useful since it turns the marketing material into an experience itself. Feeling the image is very different from seeing it.

An embossed design is also unique. It makes you stand out from the pack and can give your brand a one-of-a-kind feel that is attractive and carries pleasant connotations. In the highly-saturated grocery market, customer loyalty can go a long way. Seeing a product with a high-end feel amidst low-level ones may help customers appreciate your brand more, or at least notice it over the competition.

2. Texture and Touch

The tactile aspect of an embossed design is one of its primary benefits. Running your fingers over the indentations can be a satisfying experience for many, and several new studies are proving the value of touch in marketing and the decision-making process. People are more likely to hire candidates if they are holding a heavyweight clipboard, for example.

Having packaging with texture is another way to separate your product from the plethora of competitors on the market. It is eye-catching and makes the process of holding it as you read the label more enjoyable. Plenty of people are tactile shoppers — they like to brush their hands on everything as they walk through the store and have to feel before they buy. Embossed designs appeal especially to them.

3. Professional

We’ve touched on the ways that embossing can set your brand apart, but it can also make your materials and brand appear more professional. Embossing can make things more aesthetically pleasing and may put you on par with the classiest of companies. A professional-looking label can help you appeal to investors as well if you’re getting started.

People appreciate the extra effort that companies put into their materials. It shows a commitment to presentation and that you are willing to spend the resources on the customer experience. It gives the sense that you don’t hold back when it comes to taking care of the customer.

4. Variety

You can emboss almost any design onto many different types of materials, including fabric and leather. With a vast array of choices for foils, inks, designs, materials and presses, there are limitless options for an embossed package. Costs can also vary, providing opportunities for small and large print runs and differing complexities. The different options offer a professional, classy and affordable addition to nearly any product.

Embossing Applications

Embossing printing works well for marketing materials like mailers and business cards, but it is also an excellent option for packaging. Adding an embossed logo to the outside of a product adds an attractive element of dimension and depth. It is also an inexpensive way to make your product look a little more premium and high-end. Here are a few examples:

- Bottles: An elegant, embossed label brings class and extravagance to a bottle, holding anything from hot sauce to craft soda. A label is very versatile in the embossing options it offers.

- Boxes: Most paper material is embossable, and it can add a beautiful touch to a variety of food items, from mac-and-cheese to caviar. An embossed design can look particularly luxurious on specialty boxes like those for chocolates and wines.

- Wrappers: Yes, you can make embossed wrappers. Usually, these wrappers actually place a paper layer over an aluminum inner wrap. Treats like chocolate bars and other snacks can feature a foil-embossed logo for some color and eye-catching detail.

- Jars and containers: Though it involves a different process, you can imprint a logo or design onto thick plastics.

- Braille: A broader audience may appreciate inclusive features such as braille, to help the visually impaired.

- Freebies or promotional materials: Sending out fliers with embossed designs or slipping a find-us-online card into your packaging are other ways to use embossing. The options are nearly endless.

While this list includes what you can emboss on, here are some of the designs you can emboss:

- Logos: Depending on their placement, logos can work well as a variety of embossing styles. They may look good with foil or as a simple colorless embossing. Pairing a raised image with the standard logo printed on the material can also be an effective way to embellish it.

- Text: Sparkly lettering can be an elegant touch on a variety of packaging styles. Boxes of chocolates and liquor labels can benefit from foil-pressed lettering or general embossing. If the text is readable enough, you may be able to use no ink or foil and do a blind emboss — a technique we’ll discuss later.

- Patterns: A simple repeating pattern can make a world of difference to your packaging. It is a classy, simple way to add some variety and dimension. Whether you want a Victorian-feeling damask or eco-friendly vines wrapping around a product, patterns make for a nice texture that envelops the entire package.

- Artwork: Artwork often requires a simple, single-level emboss, or it can get lost in the details. If done correctly, this draws attention to the image, offering a unique level of dimension.

- Stickers: Have you earned a seal of approval or another type of certification? These stickers are typical on books, but you can make similar ones for food packaging. You could also call out a new design or product.

The Process

There are several different options a manufacturer has when considering how it will emboss. Effects like foils and multi-level dies can add depth, while different die materials can influence the capabilities of the print run.

In each instance, dies are pressed against wet or damp paper, with an opposing counter die on the other side. The counter die holds an impression of the master die, usually on a hard surface like epoxy. Some refer to these dies as male and female.

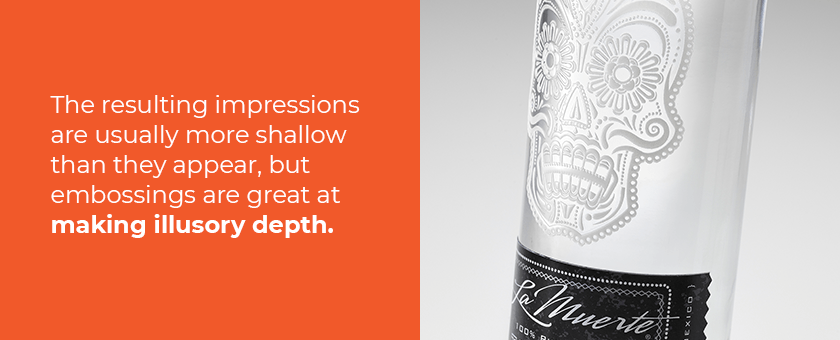

The presses can be in a few different configurations, including clamshells, stamps and rollers. The resulting impressions are usually more shallow than they appear, but embossings are great at making illusory depth. The actual depth of the design is also dependent on the thickness of the substrate.

The metals used for a master die include:

- Magnesium: This soft metal is usually etched with acid and can be hand-tooled. It is the cheapest option and may not last very long. Magnesium is good for single-level dies.

- Copper: Copper sits in between magnesium and brass, as it is harder and more expensive than magnesium, but softer and cheaper than brass. It cannot be hand-tooled but is suitable for single-level designs.

- Brass: Finally, brass is the hardest of the metals and costs the most, but it also lasts the longest. It can be hand-tooled and used for multi-level dies.

In addition to the straightforward single- and multi-level dies, they can also include beveled edges and chisels. Beveled edges give more depth and help keep the design from cutting through the substrate. These dies help to achieve a more three-dimensional effect. A chisel die is similar but doesn’t have a flat bottom. It is a simple v-shape cut into the surface. Rounded dies are another option, which dome the impression, giving it a smooth appearance.

Some of the effects you can achieve with the embossing process in printing are as follows:

- Blind emboss: Many embossings pair with inks or foil presses. A blind emboss uses neither for a more subdued, clean look.

- Registered: The inverse of a blind emboss, registered embossing pairs the relief with a printed ink design or foil cutouts. This tactic works well for added embellishment and eye-catching design.

- Combination/foil-emboss: As the name implies, in this method, a foil is pressed into the pattern wherever it is embossed. This approach gives it an eye-catching, shimmery effect that pairs well with text and accents. Gold and silver may achieve that glamorous, luxurious feel, but other colors can often help your brand imagery.

- Sculptured: A sculptured design is done on brass, as it must be hand-tooled on multiple levels. It adds depth and an organic touch but can be a costly process.

- Leaf-tint: Leaf-tinting adds what is essentially a finish to the embossed area. Also called pastelling, this method works with combination dies to add a pearlescent or glossy tone to the image. Pastelling works well for an antique effect.

- Scorching: Though a bit more complicated than other methods, scorching can provide a shaded look by applying slightly more heat to the press. If done incorrectly, this can tear or burn the paper.

- Textured: By etching in texture, you can create more organic patterns and mimic other materials. These are usually single-level designs.

Another vital component of the embossing process is the paper being used. Heavy paper with long fibers works well for embossing. Coated papers tend to crack under the pressure of the press. The paper you use can also determine which printing finishes will work best.

Designing for Embossing

A designer should consider the embossing process from the start of the design. It may be a great embellishment, but designs can quickly become crowded or wash out the embossed image if not done carefully. Avoiding too-fine lines can help keep the design crisp, and so can being careful with your font choices. Sans serif fonts work well since they have fewer additional details to worry about.

Another consideration is the file that goes to the die manufacturer. The design must be done in a vector format to ensure smooth edges and a high print resolution. The embossed area will need to be about a quarter to half an inch away from the margins to stay taut.

It also helps to remember that embossed designs have fewer finishing options. Embossing should be one of the last steps in the process.

Emboss Your Packaging With Phase 1 Prototypes

Hopefully, you’ve gotten a feel for just how useful embossing can be for your product and your brand. It can become a staple of your company or a product line, adding professionalism and uniqueness to it. Luxury products especially benefit from the classy associations that embossed designs carry. Customers appreciate the extra mile, and texture helps to develop a sensory experience for anyone who touches the product.

Embossing doesn’t have to be expensive either. It is an affordable option, and varying complexities allow you to use designs that fit your budgets. At Phase 1 Prototypes, we are familiar with the embossing process and can bring it to life in your product packaging. We offer fast turnarounds, and can typically provide an embossed packaging comp in less than three days. Learn more about our embossing approach and how it can work for your next product.

Leave a Reply