9 Challenges to Overcome in Your Packaging Process

By: phase1

Quality containers entice customers to make purchases. Conversely, poor packaging choices can lead to lower sales, reduced product quality and higher costs. Given the stakes, you must consider how you’re addressing these top nine packing issues with your container design and know when it’s time to shake things up.

You can overcome challenges in the packaging process by practicing thoughtful packaging design, changing materials, and tracking and managing expenses. Ideally, you want to strike a balance between quality and efficacy while keeping your mind on the consumer experience as you design your packaging.

Top Packaging Process Issues

Packaging must overcome multiple challenges to ensure it creates a secure container for the product while remaining aesthetically pleasing to the customer. The most pressing packaging challenges in the processes include:

- Sustainability

- Product protection

- Recognition

- Distribution

- Freshness

- Impressions

- E-commerce

- Rising costs

- Quality

See how these issues present considerations for your packaging design and what you can do about them, even for online businesses. The commercial landscape is changing, which presents more problems with packaging to companies. Almost all businesses are solely online or have a physical as well as an online presence. It’s important to keep this in mind as you evaluate how to best package your goods while managing rising costs, brand recognition and product protection.

1. Sustainability

Sustainability in packaging is even more important now with a world overwhelmed by pollution. The process of packaging has to become more sustainable to overcome modern pollution challenges. According to the Environmental Protection Agency (EPA), 29.9% of the contents of municipal solid waste landfills are product packaging, which equals 80.1 million tons of garbage. Companies today must become more aware of how their packaging affects the environment. Sustainable packaging that uses fewer raw materials, produces less waste and encourages recycling is the way of the future, and it was a central focus at the 2024 Packaging Innovations conference.

Some companies have a firm grasp on these innovations. For example, Evian reached a carbon-neutral status at some of its sites in 2020. The company changed the bottle design to reduce packaging weight and use more recycled plastic. Their product development changes between 1993 and 2018 reduced the 1.5-liter bottle’s carbon footprint by 17%. In addition, choosing recycled plastic cuts carbon emissions by 50% compared to using new plastic in their bottles. Today, the company is offering bottles made from 100% recycled plastic in select European countries as part of its mission to be fully circular.

In the United States, Keurig, Dr Pepper, Coca-Cola and PepsiCo came together at the end of 2019 to announce a joint effort to increase awareness of their packaging solutions’ recyclability and to reduce plastic waste. To educate consumers about their Every Bottle Back Initiative, the companies will add information to their packaging to remind users to recycle the containers after use. By promoting recycling and waste management, these companies reduce the need for costly virgin plastic while encouraging an increase in recycled plastics, which they use in their packaging production.

With many well-known companies investing in sustainability and advertising their efforts on their containers, packages that don’t meet these needs may lose favor with environmentally conscious consumers.

2. Protection of Goods

While sustainable packaging helps protect the planet, your packaging must protect the goods inside. Another challenge in the packaging process is keeping your products protected. Depending on the nature of your product, you may require more rigid containers than other items. Delicate products, like baked bread, may require sturdy exterior packaging to prevent crushing the products inside. Air cushions and multiple packaging layers, commonly used with potato chip packaging, are two options to consider for protecting your goods from damage.

Packaging your goods for safe transit is vital, and some inventory may require special material that’s challenging to open. Examine how you can best balance keeping your products safe while providing a pleasant customer experience.

3. Recognition

Consumers must know your product and product category from the packaging alone. Making the package design or graphics too similar to another product could create packaging process issues and cause confusion. For instance, in 2010, the U.S. Food and Drug Administration sent a safety announcement on Benadryl’s topical skin gel. The bottle and package design for the gel closely resembled that of Benadryl’s oral medication. The warning prompted the company to repackage the skin gel into a tube to distinguish it from its oral product.

Brand recognition is also crucial in the packaging. Consistent branding increases a product’s worth by 20% compared to goods that do not maintain a recognizable brand. Old Spice felt the adverse effects of inconsistency when they changed their cologne packaging. For years, Old Spice cologne had a glass container. The company switched to plastic containers to reduce packaging weight and prevent shattering. Consumers, however, did not appreciate the change. The plastic no longer matched the old-fashioned branding of the fragrance. Some likened the shift to boxed wine.

4. Distribution

In 2017, industry expert Ken Chrisman predicted companies would require packaging solutions that could go directly to the consumers without the need for pallet storage. Product distribution presents unique challenges in the packaging process. The rise of e-commerce and the need for direct shipment to buyers’ doorsteps—instead of sending goods between warehouses—means that packaging must stand up to movement while keeping the products inside safe.

In more oversized packaging for bulk goods, containers cannot exceed amounts that workers can safely handle. If they do, warnings to lift using assistance or a forklift should appear on the package. For example, while a worker can move a box containing a wide-screen television alone, doing so could damage the product. The packaging should encourage the worker to get help handling an easily harmed good.

Distribution considerations also play essential roles in designing food packaging. Not thinking about protecting the food inside for temperature-sensitive products can lead to spoiled foods or recalls once they arrive at the store. One company that looks beyond the production line is the U.K. market Tesco. The store developed packaging to maintain product temperature from production throughout the entire distribution chain to the point of sale. Keeping the ideal storage temperature through better packaging helps the company ensure quality when customers purchase products.

5. Freshness

Freshness is vital for the food industry. Packaging process challenges arise when producers don’t take freshness fully into account. Though some foods remain safe to eat for months, they may have a shorter shelf life for optimal flavor and freshness. Packaging must account for keeping the goods at their peak until purchase.

One package that catered to freshness was the solution chosen by the Lebanese dry fruit and nut company Alrifai. The company faced a product recall of its pistachios after their initial package design caused the nuts to rancid before purchase. A packaging redesign prevented the need for more recalls because it kept the nuts fresher and allowed consumers to see inside through a clear viewing panel.

Another packaging story from Lipton holds a warning about product freshness. When the company redesigned its 100-count teabag box to have four gold, foil-wrapped sleeves of 25 bags each, the new design didn’t support optimal product use. Once a consumer opened one of the sleeves, the remaining tea bags would quickly lose their freshness. This story proves that sacrificing freshness in exchange for aesthetics is not advantageous.

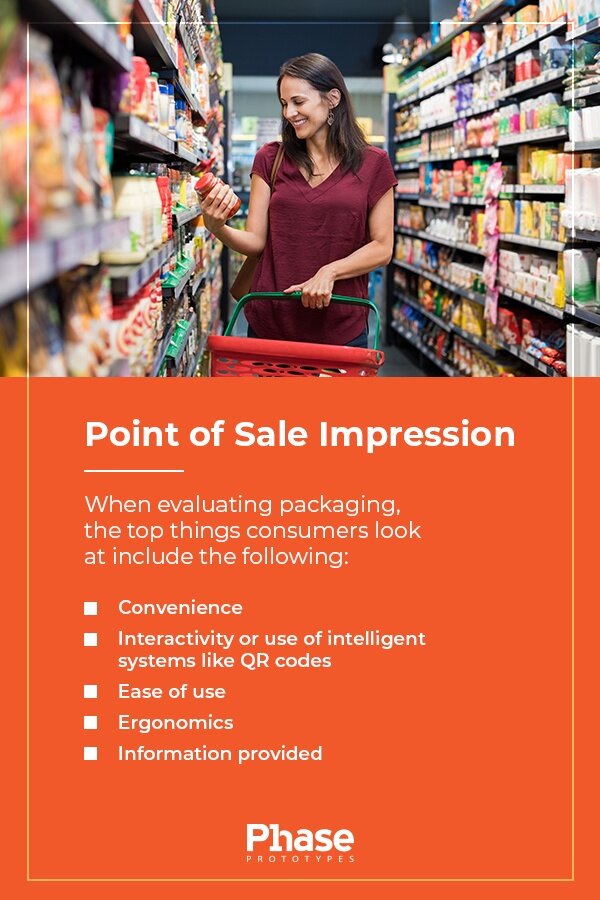

6. Point of Sale Impression

A consumer’s impression at the point of sale significantly influences whether they purchase a product. For 60% of shoppers, packaging encourages them to buy. Additionally, if they had a positive experience with the packaging on their first purchase, 41% of consumers will repurchase the product.

When evaluating packaging, the top things consumers look at include the following:

- Convenience

- Interactivity or use of intelligent systems like Q.R. codes

- Ease of use

- Ergonomics

- Information provided

Changing package design to make it more enticing to consumers has valuable benefits. One company that took advantage of a redesign was Unilever when it sought to update the packaging for its U.K. brand of fabric softener, Comfort. The formula became a more concentrated version, Comfort Intense, which required less packaging. To make the product stand out on the shelves, designers chose a bold color scheme and information indicating its highly concentrated state.

The company recognized how successful the teardrop-shaped bottle with bright colors was because it sold at a 32% higher cost compared to the standard Comfort. Consumers still purchased Comfort Intense despite its smaller size and higher price because the packaging effectively communicated the premium strength of the product. Within eight weeks of its introduction to stores, Comfort Intense had strong sales, with a 9% market share.

Consumers appreciate the use of colors on packaging:

- For 85% of shoppers, color drives their purchase.

- For 93% of customers, the product’s visual appearance is what they focus on.

While bold colors draw the eye toward the packaging, don’t overwhelm the consumer with information. Industry expert and veteran of Nestle, Lars Wallentin, suggests keeping packaging simple with only enough information for the consumer to absorb in 10 seconds.

Ease of use for packaging is another critical factor consumers quickly examine when shopping. Hard-to-open packages are a pet peeve of 55% of consumer respondents to a packaging survey. Changing to products with easy-to-open lids or containers that consumers can easily hold may improve sales.

Health claims and other wording on packages must boldly and clearly state what the consumer can expect in simple terms. When Sun-Maid redesigned its raisin and dried fruit packaging to appeal to a millennial demographic, it added health claims, such as 0 grams of added sugar and whole fruit. The company stated it would keep the red box for raisins but move toward using pouches for its other dried fruit products. Consumers preferred the pouches for the extra convenience of a resealable container when snacking. The redesign, which didn’t disrupt the brand’s recognition with consumers, has gotten positive feedback from shoppers.

7. E-Commerce

One of the most significant packaging process challenges consumers and companies face is managing the overabundance of packaging used for shipping goods ordered online. To avoid generating excessive waste from cushioning material, consider choosing packaging that does not require additional shipping containers or use biodegradable packing materials.

When dealing with e-commerce shipping boxes, you want a package that maintains brand recognition without damaging the product. For example, Bloom & Wild Flowers wanted a distinctive package design that would protect the company’s flowers while still fitting through a letterbox opening. They achieved this goal with the help of design iterations and packaging prototypes. These shipping and protective challenges are common for e-commerce product package designs.

Another concern with e-commerce is whether to design a separate package for online sales. If you predict considerable e-commerce sales in addition to brick-and-mortar store sales, go with an omnichannel package design that you can use in both markets. Such a design will only require one stock-keeping unit (SKU) instead of multiple.

8. Rising Costs

One of the biggest challenges in the packaging process is the rising cost of packaging materials, which is directly affected by the elevated price of paper products. Your business can address this price increase in a few ways:

- Omni-channel packaging: You can choose a single design for multiple sales channels to cut costs.

- Reduced packaging: You can redesign to use less packaging. By reducing the amount of packaging, you spend less on materials.

- Redesigned packaging: Some packaging may cost more due to special features like a 3D texture, but the boost in sales compared to less eye-catching goods may help recover the extra investment.

- Sustainable packaging: Sustainability helps to cut rising costs by using more affordable recycled materials and lighter-weight products.

- Lighter-weight packaging: Lower product packaging weights help to cut shipping costs, which often tie closely to the volume or weight of the products sold.

Though rising costs may continue, you can overcome this hurdle through careful planning and by following guidelines for quality containers.

9. Quality

The quality of your packaging affects how well customers engage with it. Your packaging should entice consumers at the point of sale and leave a lasting impression when they unbox or open their goods at home. Look out for some of these factors in the packaging process to ensure you maintain high standards of delivery:

- Tailor your packaging: Package your fragile goods differently than you do your more robust products. Incorporate strong, high-quality material for all your inventory and ensure the material can withstand handling.

- Easy-to-open products: Prevent your end users from getting frustrated by spending some time on the opening experience of your packaging. Evaluate how customers should open the product, and if the current style makes them resort to scissors or knives, try a redesign.

- High-quality materials: Consumers can quickly identify if the material you use for your packaging is high-quality, and it will affect their perception of the product. Additionally, low-quality packaging stands the risk of tearing and breaking in transit. Cleverly designed packaging with strong materials can help your brand.

- Strike the right balance: It’s important to strike a balance between using premium material to avoid packaging process challenges and keeping costs in check. Fortunately, there’s no need to spend thousands to boost the quality of your packaging, as minor changes and smart design can go a long way to ensure quality.

Overcome Your Biggest Challenges in Packaging With a Quality Prototype

Packing problems come in many forms. Consumers pay close attention to the visual appearance of your package design. Keep your labels informative, colorful and straightforward to avoid overwhelming your potential customers. In addition, try not to make packaging so different that it changes your brand recognition or makes the product difficult to use. Because you have many factors to consider, you will likely go through multiple designs before settling on a final form.

A 2D computer image cannot adequately display whether you’re addressing containment issues when designing your package. You need a prototype to see if your packaging offers the desired customer experience. During testing, you can use the prototype to gauge levels of customer interactivity while seeing how well the design presents issues and acts as a packaging problem solution.

For a quality prototype of your design, reach out to us at Phase 1 Prototypes. We can send you a free quote in 24 hours, and after getting your final designs, we can have your prototype packaging shipped in three days or fewer. Our professional services help you deliver your product and packaging to the market faster. We’re equipped and excited to help you realize your packaging vision. Contact us today for a free quote or to begin the prototype process for your packaging design.

Leave a Reply